Industrial Spray Dryer

Flat Bottom Spray Dryer

Flat bottom spray dryers are especially designed for the processing of flavours, foods and other similar heat sensitive products requiring the highest quality standards and rigid control of the volatile product in the dry product. The variable speed control sweeper arm at the bottom of the dryer lets you accurately control powder residence time in the drying chamber.

Standard Model Spray Dryers

The small manufacturer in the past couldn't afford a spray dryer due to capital and installation cost. To cater to these needs, we have through cost effective modern engineering, fabrication and installation methods developed six standard models and made spray dryers affordable.

For dilute and thermally sensitive solutions such as fruit juices, tea extract and pharmaceuticals, spray concentrators are offered prior to spray drying.

Centrifugal Disc Atomiser

Atomization of feed is the heart of spray drying. Spinning disc type of atomizer is more widely used. Atomization occurs as the liquid feed flows off the edge of the spinning disc. This is ideal for producing spray dried powders of fine to medium particle size.

- Air cooling for interior of atomizer.

- Discs designed to minimum weight exhibit lowest internal stresses and permit maximum bearing life in the driving unit. Maximum disc speed is 12,000 rpm.

- Dryer has steep cone bottom for free flow powder.

- Special reinforcement structural allow drying chamber to expand hence no dent is formed during expansion & contraction.

- Multi cyclone design gives better recovery of product.

- Single point collection to minimize dusting

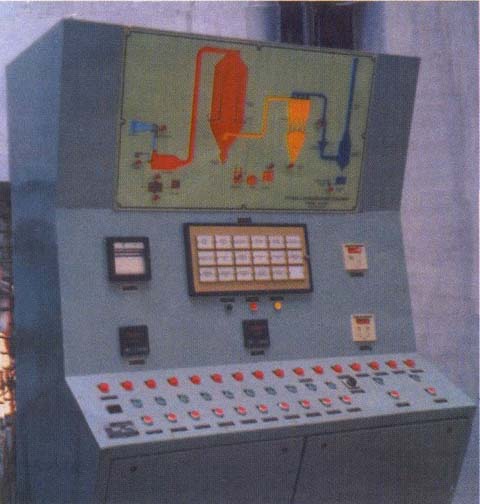

- Automatic temperature and feed rate controls.

- Plants are designed in closed cycle version for drying feed containing organic solvents.

- Aseptic design offered for pharmaceutical application.

| Model No. | Water Evaporation [Lit / Hr]* | Heat Required [Kcal / Hr] | Installed Power [HP] | Space Required in Meters WxLxH |

|---|---|---|---|---|

| 806 | 50 | 67,500 | 10 | 4.0 X 4.0 X 6.5 |

| 1008 | 100 | 1,30,500 | 18 | 4.5 X 5.0 X 8.0 |

| 1210 | 200 | 2,52,000 | 30 | 5.0 X 6.0 X 9.0 |

| 1512 | 400 | 4,95,000 | 45 | 6.0X 6.5 X 11.0 |

| 1814 | 600 | 7,20,000 | 70 | 7.0 X 7.5 X 12.0 |

| 2016 | 1000 | 11,96,280 | 100 | 8.0 X 8.5 X 13.0 |

Gallery