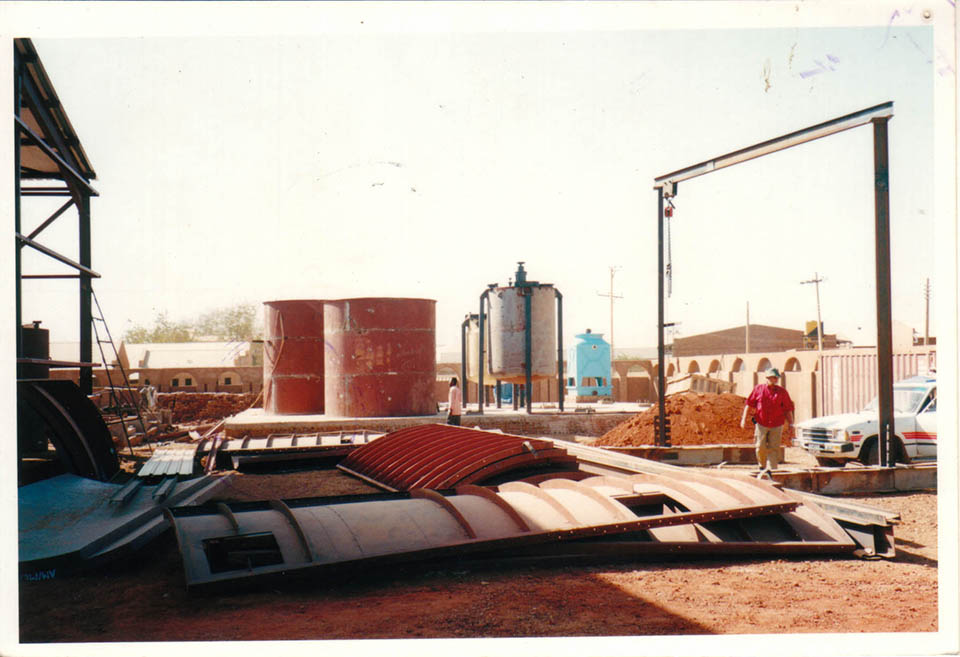

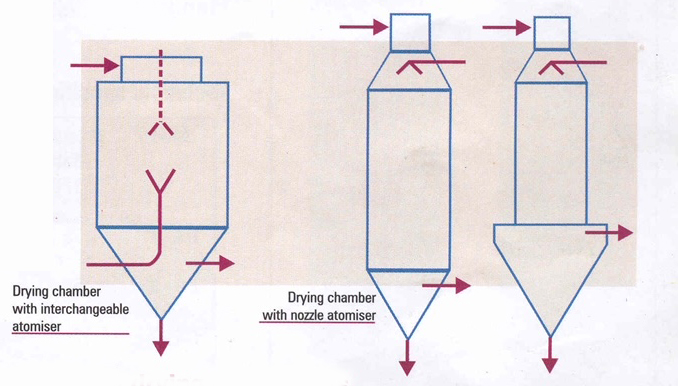

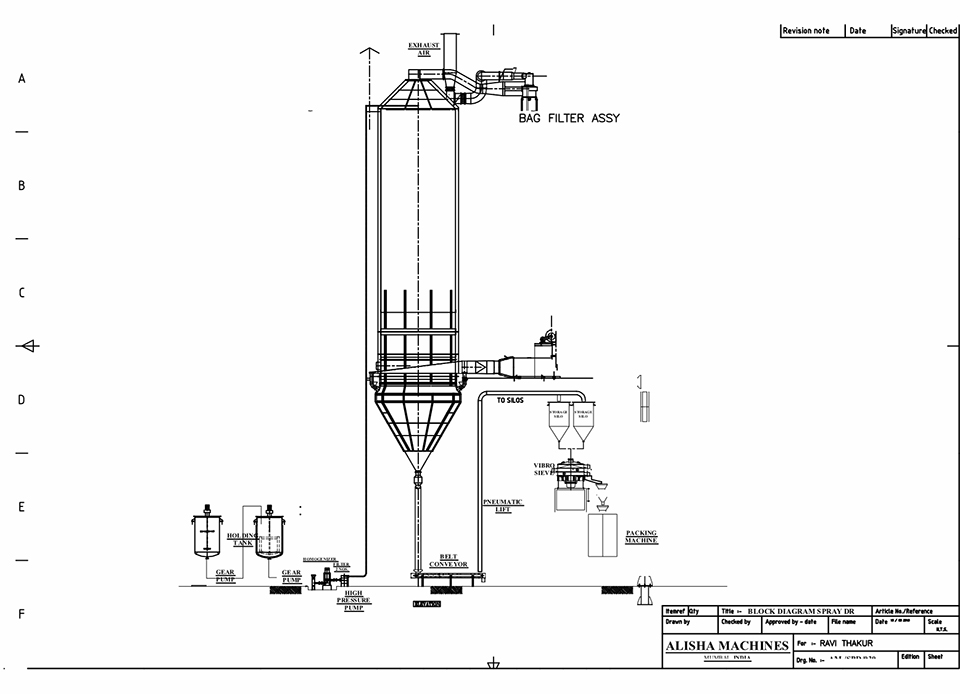

Tower Model Spray Dryer

Tower Spray Dryers meeting low dust and high bulk density requirements.

Tall form dryers are used exclusively with nozzle atomizers in drying products that include milk, coffee, dyestuffs, detergents, ceramics and chemicals. Tower dryers have different chamber construction with respect to air distribution, product air separation and nozzle mounting.

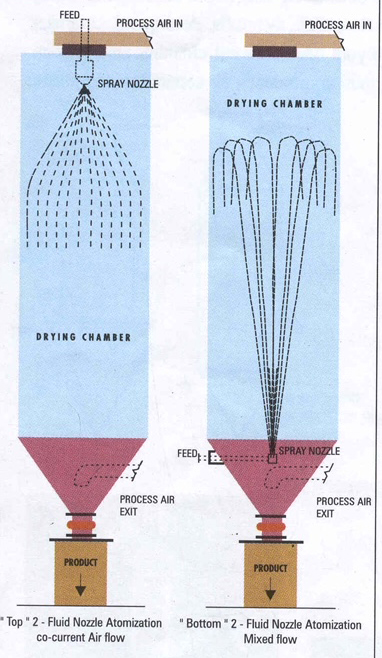

Two basic types of nozzles are commonly used in spray drying equipments.

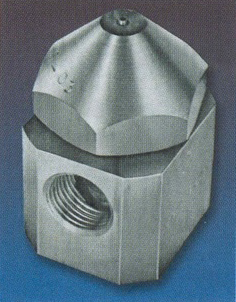

Pressure Nozzle

Pressure nozzle or single fluid nozzle use pressure energy for atomization, with feed pressures in the range of 200 to 600 psi. The pressure energy is converted into kinetic energy and the feed issues from the nozzle has a high-speed film which readily breaks. The pressure nozzles are suitable for feeds with relatively low viscosity and free of lumps.

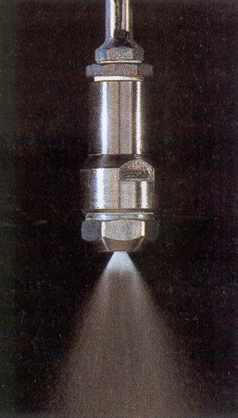

Pneumatic Nozzle

Pneumatic or Two Fluid Nozzle use compressed air to provide the energy required for atomization. Compressed air pressure is usually in the range 20 100 psig. Feed pressure requirement is low and viscous feed is handled successfully. In pneumatic nozzle the feed can be mixed with compressed air either internally or externally. The external mixing types are used for abrasive feeds. Two Fluid Nozzle atomizer are convenient for low capacity application and popularly used for high quality ceramic powders Alumina, Bentonite, Carbides, Clays, Ferrites, Steatites, Titanates and Zirconias.

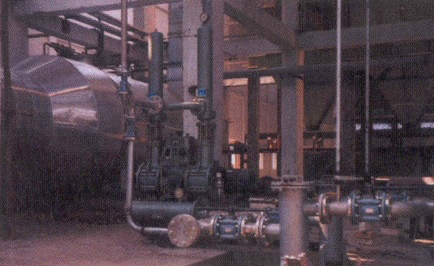

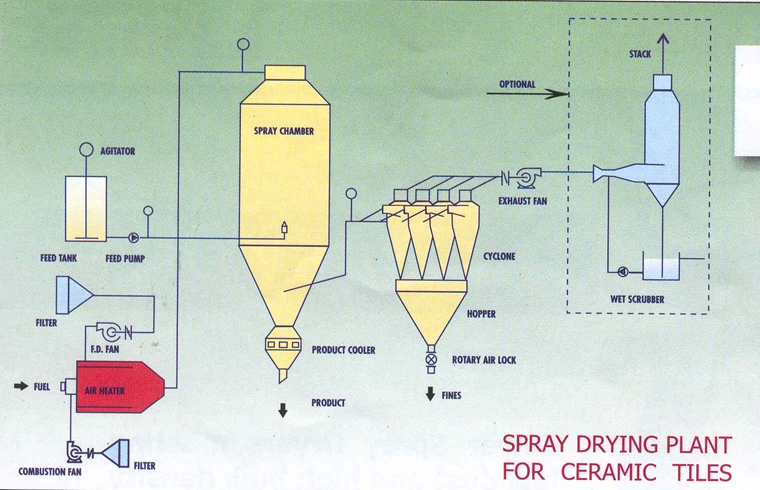

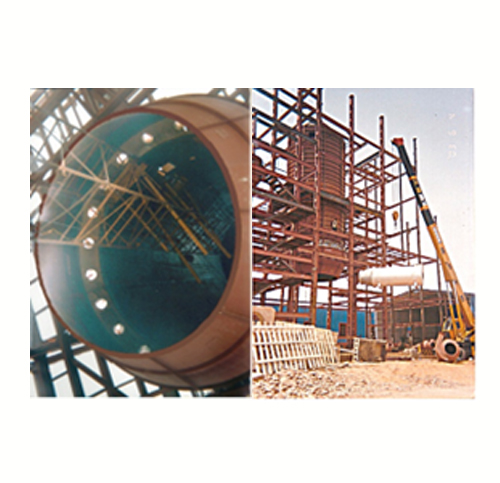

SPRAY DRYING PLANT FOR CERAMIC TILES

The design involves stainless steel construction for hot air and product contact parts, large size drying chamber, high performance cyclone separators, direct type hot air generator for air temperature up to 600 C, extremely reliable feed pump and spray nozzles, venturi scrubber as an optional secondary collector.

Specifically to cater to the needs of Tile Industry, we have standard models covering water evaporation up to 4800 LPH.

| Model No. | Production Rate* [TPD] | Water Evaporation [Lit / Hr]* | Heat Required [Kcal / Hr] | Installed Power [HP] | Space Required in Meters WxLxH |

|---|---|---|---|---|---|

| DS-1 | 25 | 600 | 5,10,000 | 30 | 10 X 12 X 18 |

| DS-2 | 50 | 1200 | 9,75,000 | 50 | 12 X 15 X 18.5 |

| DS-3 | 100 | 2400 | 19,20,000 | 90 | 15 X 20 X 20.5 |

| DS-4 | 150 | 3600 | 28,80,000 | 120 | 15 X 20 X 21 |

| DS-5 | 200 | 4800 | 38,40,000 | 165 | 15 X 20 X 22 |

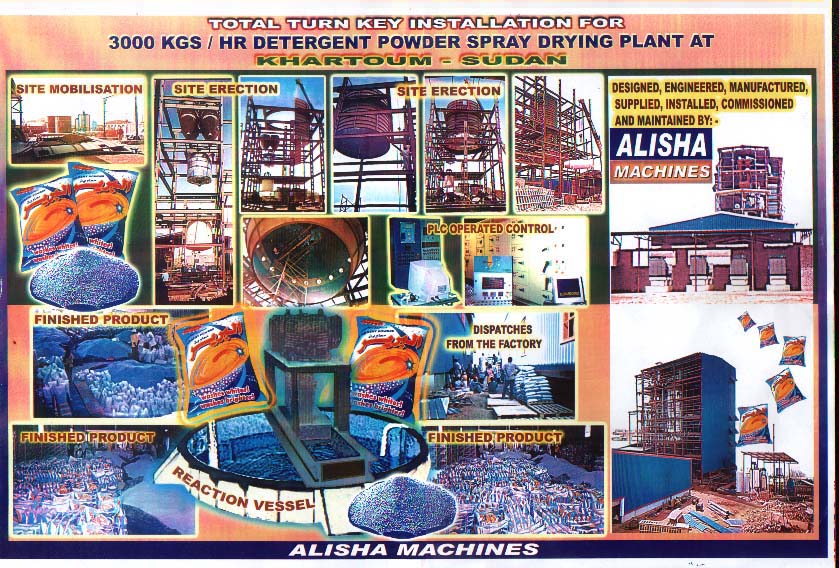

Gallery